PC-based control as a complete solution for packaging line automation

The Italian ESN Group specializes in integrated solutions for the automation of packaging lines, which involves labeling, packaging, palletizing and handling products within a production plant. The company relies on control and drive technology from Beckhoff at every stage, confident that it is the ideal choice for meeting the requirements of modern modular machine building on account of its openness, flexibility and high-quality standards. It also values the close cooperation that has been established with Beckhoff since the very first project.

The history of the ESN Group is that of a classic startup: Founded only four years ago in Treviglio in northern Italy, ESN (Engineering Service Network) comprises a number of specialized partner companies along with all of their combined expertise and experience. The result is turnkey, customized end-of-line solutions for packaging processes that notably include machine modules for labeling, primary and secondary packaging, palletizing and handling in sectors including the food, chemical, pharmaceutical, pet food and mineral oil industries.

Focus on medium and low machine cycles

“Our aim is to serve customers primarily in the medium- and low-speed machine segment,” explains engineer Glauco Cima, co-founder and CEO of ESN. “This market segment offers real scope for innovation and performance improvements with the help of modern automation technology.”

The ESN philosophy is expressed in a particular interpretation of the term ‘end-of-line’: The packaging process is not seen as several machine modules strung together, but rather as a modular and integrated system that is capable of communicating detailed information about its operation through a combination of classic automation systems and modern combined OT/IT architectures. “Many companies simply combine several individual machines,” explains Glauco Cima, outlining the basic problem. “However, this approach results in valuable information that is crucial to the management and performance of a line being lost to shift and production management.”

The ESN concept of an end-of-line plant includes all of the aspects that are necessary for the final packaging process:

- labeling and appropriate controls

- product quality controls

- handling

- palletizing

- secondary packaging

- pallet control

- pallet coding and traceability

“The integrated management of each of these process flows in our concept is so important, as it provides end customers with all of the information they need in real time, incorporated into the rest of the production environment,” explains Glauco Cima, highlighting the modular approach. “A variable concept like this requires automation technology that is equally modular, open and flexible. And with that in mind, PC-based control from Beckhoff has proven to be the best solution when it comes to putting this all into practice.”

Technology supplier and automation partner

“We are familiar with systems from other suppliers, but we were looking for a solution that is reliable, simple and open,” notes Glauco Cima. This ruled out traditional PLCs from the outset. But there was also another aspect to consider: “As a startup, we were looking for a very dynamic kind of support, especially in the beginning,” the ESN managing director says, “and Beckhoff really was – and is – one of the most dynamic companies out there. This is true not only in terms of innovation and market approach, but also in terms of support for companies dealing with special projects and requirements, like ESN.”

According to Glauco Cima, from a technical point of view, Beckhoff automation solutions represent the best on the market for ESN in terms of quality, modularity, compactness and openness. They are also the perfect fit for the machine builder’s automation philosophy and the motion requirements that are typical in the packaging industry. “I should also point out that our cooperation with Beckhoff has been incredibly close from the start, and this level of trust is so important to us,” enthuses the ESN managing director. “We only ever use Beckhoff automation technology for our projects, from drives to decentralized I/O and from TwinCAT automation software to operator interface panels.”

A modular system for modular machines

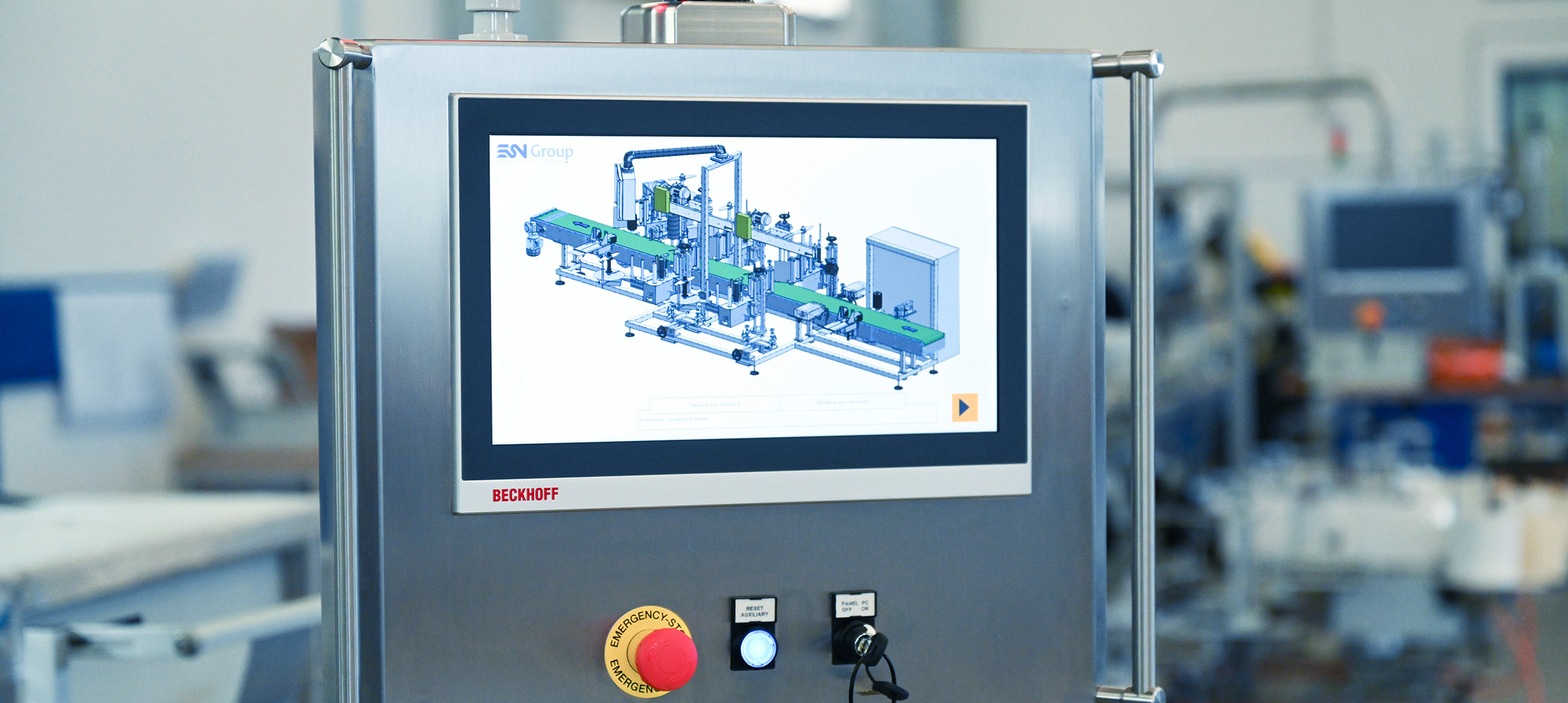

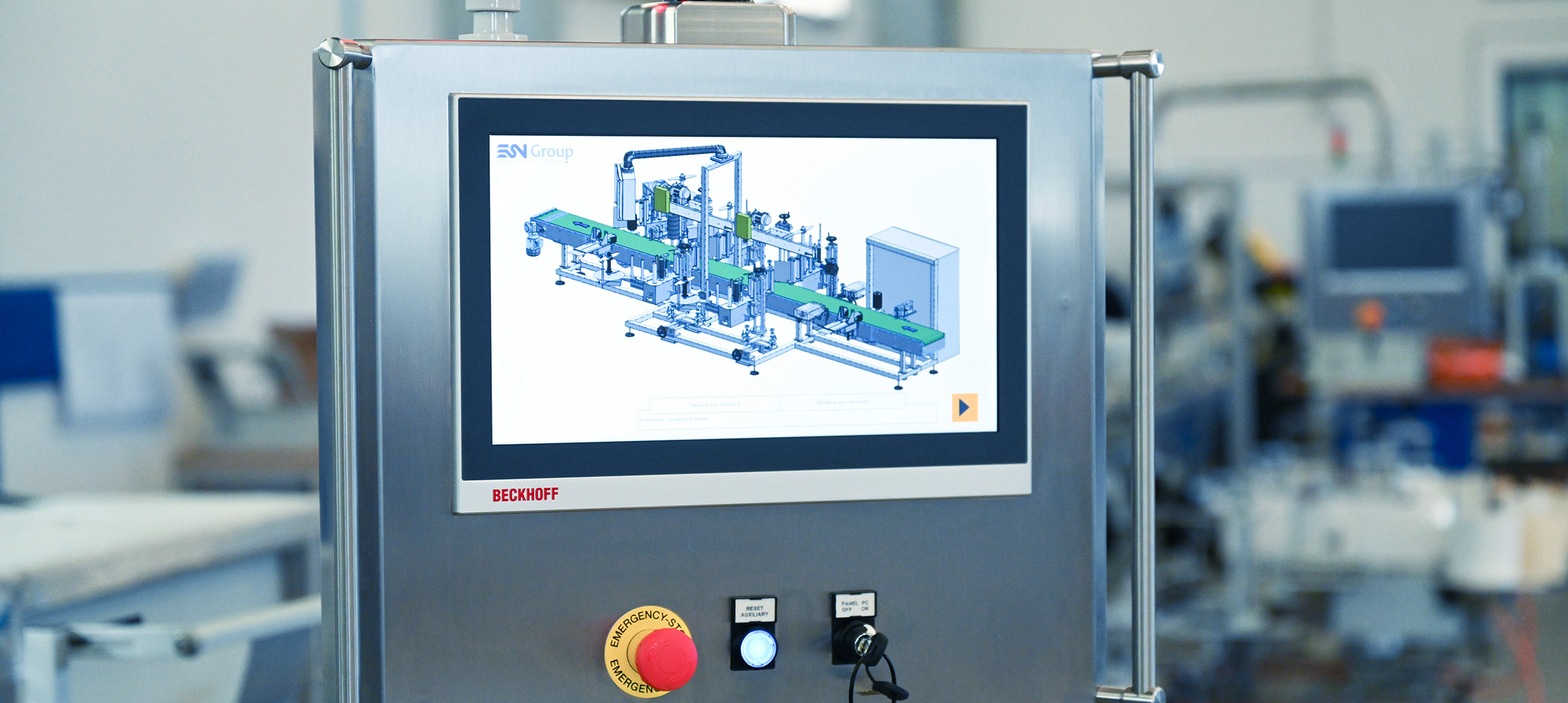

In ESN’s typical end-of-line concept, each module uses a Panel PC as a controller – a CP27xx multi-touch built-in unit or a CP67xx single-touch ‘economy’ version. Glauco Cima explains: “We decided to combine all of our components into a modular system, which means the end of the packaging line resembles a network of compact Panel PCs that communicate closely with each other for maximum performance, traceability and quality control. Without this modular approach, it would have been difficult to achieve this goal cost-effectively and without a considerable amount of effort.”

The entire ESN automation concept is based on TwinCAT software, which also supports quality control applications such as vision systems. The openness of TwinCAT means it is also possible to integrate external projects developed in C++ or Python, for example. Depending on the specification, the control architecture can process an almost unlimited number of I/O data points connected via EtherCAT Terminals or box modules. Third-party controllers can also be seamlessly integrated via EK1100 EtherCAT Couplers if required. This system openness enables line expansions without the need for automation equipment changes, which is a vital consideration for ESN projects. The compact drive technology from Beckhoff also continues to be used in the form of EL72xx Servomotor Terminals and AM81xx Servomotors, as well as AX5000 Servo Drives with AM8000 Servomotors. This is where One Cable Technology (OCT) comes into play to minimize both cabling and installation effort.

The high performance of EtherCAT and PC-based control offers a number of further advantages – for example, ESN was able to develop an innovative quick-change system for grippers, which reduces production line downtime by allowing I/O signals to be interrupted briefly during operation.

Commissioning machines in record time

The extensive features of Beckhoff technology also shorten the development and implementation time of the projects, as Glauco Cima explains: “This is a very important aspect for being able to deliver custom solutions based on a standardized architecture.” This philosophy has been applied to mechanical and electrical plant components alike. As such, the quest for modularity at ESN starts with the design process; it is only at the end that the line is specialized, almost tailored to the process. PC-based control from Beckhoff also makes a crucial contribution to the implementation of this engineering philosophy, as Glauco Cima confirms: “This style of automation fits perfectly with our own concept and offers a suitably modular platform for following precisely this approach in the development of all projects.”

Intelligent modularity becomes mandatory

For Glauco Cima, there is simply no alternative to this concept: “The packaging industry is changing rapidly – just like all sectors that rely on advanced technology.” He is convinced that the mechanical elements of a machine will become less important in the coming years. Constraints and ‘architectural barriers’ within companies will increasingly fade away and production will have to be flexibly programmable. The consequence of this is that modularity will become a fundamental feature of a machine. “And in all applications where mechanics hinder an approach like this, electronics and reprogramming will eliminate – or at least circumvent – this shortcoming. The technologies provided by Beckhoff are perfect for this, but they are often still underutilized compared to their full potential,” says Glauco Cima.

With all of this in mind, the future development of the ESN Group is closely linked to Beckhoff’s dynamic approach to innovation. “From the very beginning, our choice was guided by the continuous innovations driven forward by Beckhoff, but fast forward to today and we still have no doubt that Beckhoff is our ideal partner and will certainly remain so for years to come,” asserts Glauco Cima, confirming the Group’s commitment to this strategic partnership.